Mohala oa Tlhahiso ea Lehong le Plastiki PVC Foam Board

Selelekela

Lehong le Plastiki PVC Foam Board Production Line/

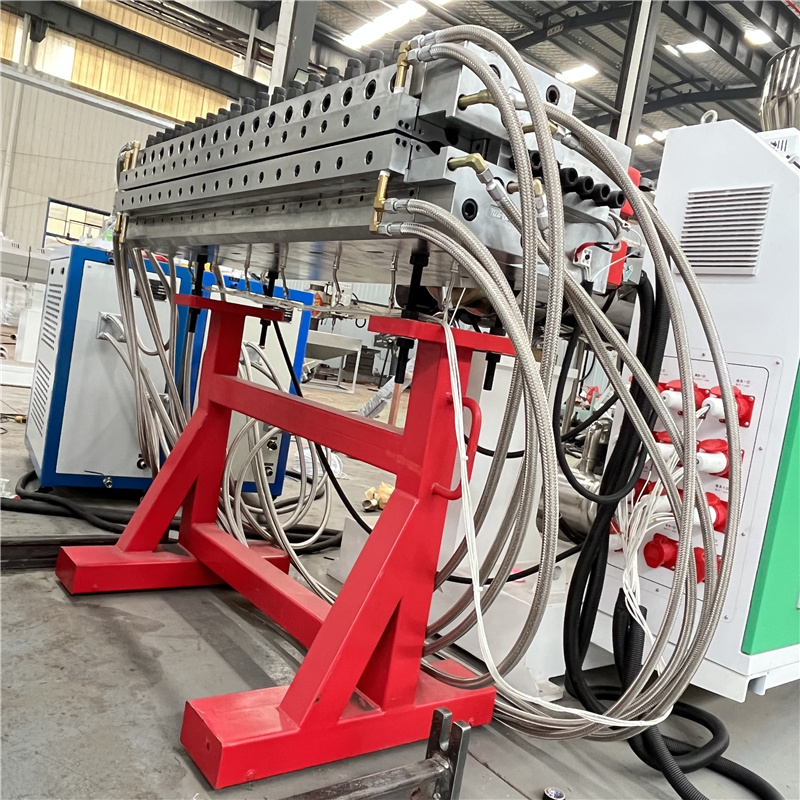

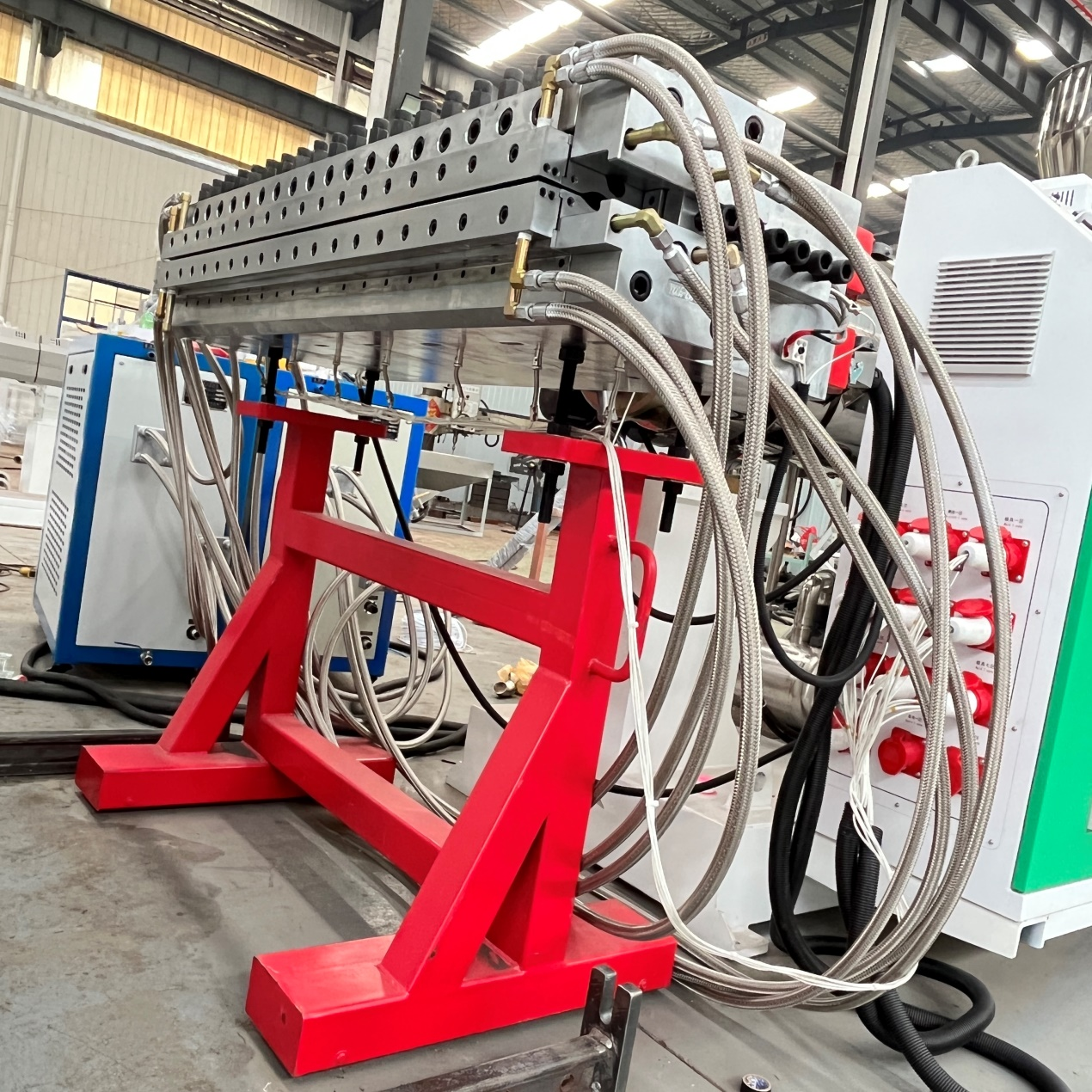

Plastic boto extrusion mola e sebelisoa ho hlahisa polasetiki boto le bophara ho tloha 600 ho 1250mm, tse atlehang, safeCapacity: Conical mafahla-screw extruder, loketseng bakeng sa tshebetso PVC phofo le phahameng bokgoniDiameter: Re na le katleho haholo tlhahiso phihlelo.Mochine o thusang haufi-ufi kopana moreki. litlhaloso.Ponahalo e ntle, taolo ea othomathiki le ts'ebetso e tsitsitseng ea ho matha.

Mochini oa boto oa PVC / WPC o ka tsoela pele ho hlahisa PVC WPC foam board.Mohala ona oa tlhahiso o entsoe ka extruder, hlobo, sethala sa calibrating, foreimi e pholileng, mochini oa ho hula, mochini oa ho itšeha le stacker.

Moreki a ka boela a hlahisa A + B + A mekhahlelo e meraro co-extrusion foam board ka ho eketsa extruder le distributor .Mochine o lokela ho hlomella ka chiller ea metsi, o ka eketsa katleho ea tlhahiso.

Mochini oa rona oa Tlhahiso ea Boto ea PVC Foam Core

e kenyelletsa e khethehileng Twin-screw extruder, hlobo le mechine e meng e thusang.Feme ea rona e sebelisa li-twin-screw extruder e nang le sebopeho se kopaneng, ts'ebetso e phahameng.Ntle le screw le barrel le die li entsoe ke k'hamphani ea rona mme li entsoe ka baetsi ba tummeng lefatšeng.'Me u sebelise tšepe ea alloy e sebetsang hantle bakeng sa ts'ebetso ea litsebi.Kahoo mochini o na le melemo ea polasetiki e ts'oanang, extrusion e tsitsitseng, tlhahiso e phahameng, le bophelo bo bolelele.Re ka u fa tlhahiso e ntle ka ho fetisisa ea thepa le theknoloji eohle.Re na le mefuta e likete tse 'maloa ea foromo ka lipatlisiso tsa lilemo tse 15.Mohala oa tlhahiso ea boto ea foam ea PVC kapa WPC e nang le tlhahiso e kholo, extrusion e tsitsitseng, foaming e phahameng, sebaka se setle le se sa tsitsang, joalo-joalo.

| Lenane la Mechini | |||

| Che. | Lebitso | Qty. | Ela hloko |

| 1 | Screw loader bakeng sa extruder | 1 | |

| 2 | SJZ 80/156 conical twin screw extruder | 1 | |

| 3 | Setsi sa hlobo sa Extrusion | 1 | 1220*2440 |

| 4 | Lethathamo la Vacuum calibration | 1 | |

| 5 | Barakete e phodileng | 1 | |

| 6 | Tlosa yuniti | 1 | |

| 7 | Sesebelisoa sa ho itšeha ka bohale | 1 | |

| 8 | Tracking cutter | 1 | |

| 9 | Mochini o ikemelang oa phetoho | 1 | |

| 10 | Sesebelisoa sa pokello ea lerōle | 1 | |

| 11 | Selaoli sa mocheso oa hlobo | 1 | |

| Mochini o thusang | |||

| 12 | Sehlopha sa SRL-Z Series Mixer | 1 | Matla: 450-550kg/h |

| 13 | Screw loader bakeng sa Mixer | 1 | |

| 14 | Mohlakodi | 1 | Matla: 11kw, 22kw, 30kw |

| 15 | Pulverizer | 1 | Matla: 45kw, 55kw, 75kw |

Mohlala oa Extruder

| Ntho | SJSZ 65/132 | SJSZ 80/156 | SJSZ 92/188 |

| Screw Diameters(mm) | 65mm/132mm | 80mm/156mm | 92mm/188mm |

| Karolelano ea L/D | 22:1/25:1 | 22:1/25:1 | 22:1/25:1 |

| Sephetho(Kg/h) | 160-200 | 250-350 | 400-500 |

| Main Driving Power(kw) | 37 | 55 | 110 |

| Phofo e futhumatsang(Kw) | Libaka tse 4, 20kw | Libaka tse 5, 38kw | 6 libaka, 54kw |

Kopo

Mokhabiso oa ka hare:boto ea thepa ea ka tlung, boto ea mamati, khabinete ea kamore ea ho hlapela, khabinete ea kichineng, boto ea mekhabiso ea lapeng, lishelefo tse fapaneng tsa ntlo, boto ea ofisi;

Indasteri ea lipapatso:khatiso ea skrine, mongolo oa k'homphieutha, boto ea lipapatso, poleiti ea lipontšo, poleiti ea log;

Indasteri ea lipalangoang:sekepe/sefofane/base le terene e kwahelang fatshe, lera la motheo, poleiti ya mokgabiso ya ka tlung;

Indasteri ea Kaho:template ea kaho, projeke ea bopaki ba ho bola indastering ea lik'hemik'hale, karolo e bōpehileng joaloka mocheso, boto ea ho kenya letsoho, poleiti e khethehileng ea tšireletso e bolokang serame.