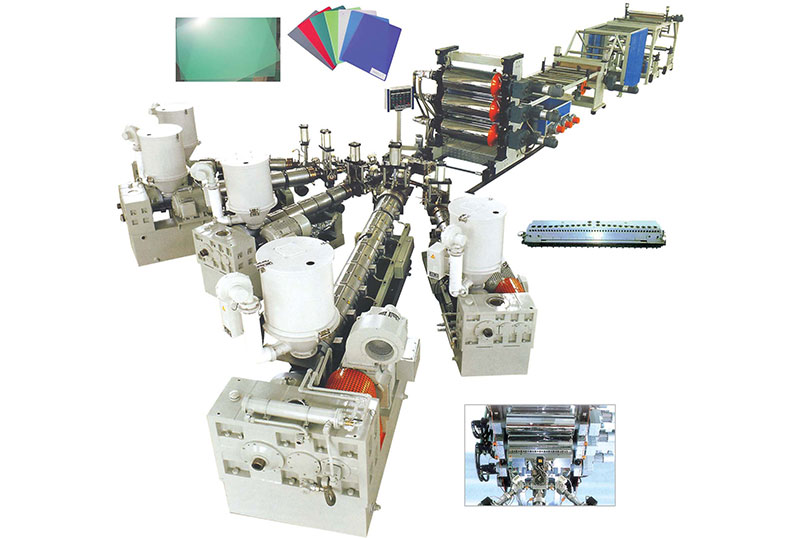

WPC PVC Crust Foam Board Extrusion Line

Lintlha tse qaqileng tsa Tekheniki Parameters

(Setšoantšofeela bakeng sa litšupiso)

Tlhaloso e akaretsang

1, Sehlahisoa sa boholo: bophara 1250mm / botenya: 2-30mm (Ho ipapisitsoe le tlhokahalo ea moreki)

2, Boitsebiso bo ka Sehloohong: Motsoako oa WPC, li-additives le ho tlatsa

3, Extruder: SJSZ80/156 conical double screw extruder

4, Output: ho pota 7ton / letsatsi

5, Mocheso oa metsi a pholileng: <15 ℃ khatello ea moea: > 0.6Mpa

6, Phepelo ea matla: 3Phase / 380V/50HZ (Ho ipapisitsoe le tlhoko ea moreki)

B.Detail Technical parameters ea E mong le e karolo

1. Screw Automatic loader

2. SJSZ80/156 Conical Double Screw Extruder

| ﹡ Screw, moralo oa libarele le tlhahiso e nka theknoloji e tsoetseng pele ea Europe ﹡ Screw le barrel thepa: 38CrMoAlA, Nitriding e tšoaroa ﹡adopt lisebelisoa tsa motlakase tsa mantlha tse nang le boleng bo holimo bo tsitsitseng.Mohlala: Molaoli oa mocheso oa RKC kapa Omron, molaoli oa lebelo oa ABB, sekhechana sa motlakase o tlase se amohela Schneider kapa Siemens ﹡Gearbox e amohela torque e phahameng, lerata le tlase, lebokose la lisebelisoa tse thata tsa sefahleho ﹡Sistimi ea ho itšireletsa: tshireletso ya hona jwale ya motor overload jarolla ka ho iketsa "screw displacement" ka ho iketsa setopong tšireletso Sesebediswa sa alamo sa ho tlotsa oli se otlolohileng | |||

| 1 | Screw Diameter | mm | ¢80/156 |

| 2 | Bolelele ba Screw | mm | 1800 |

| 3 | Lebelo la ho potoloha | r/mets | 0-37 |

| 4 | Thepa ea Screw le Barrel | / | 38CrMoAlA Kalafo ea Nitrojene |

| 5 | Botebo ba nyeoe ea nitration | mm | 0.4-0.7mm |

| 6 | Ho thatafala ha nitration | HV | 》950 |

| 7 | Bokhopo ba bokahodimo | Ra | 0.4un |

| 8 | Ho thatafala ha li-alloys tse peli | HRC | 55-62 |

| 9 | Botebo ba li-alloys tse peli | mm | 》2 |

| 10 | Matla a ho futhumatsa | KW | 36 |

| 11 | Barrel Heating | / | Ho futhumatsa Aluminium Heater |

| 12 | Screw core control control | / | Taolo ea mocheso oa potoloho e iketsang |

| 13 | Libaka tsa ho futhumatsa | / | 4 |

| 14 | Ho phodisa | / | phodiso ya sefutho |

| 15 | Screw core ho lokisa mocheso | / | Ka oli ea conduction ea selikalikoe |

| 16 | Screw quantity | 2pcs | |

| Foreimi ea mochini | Ho cheselletsa phala ea tšepe le poleiti ea tšepe | ||

| Lebokose la gear | |||

| 1 | Tekanyetso e sebetsang | / | JB/T9050.1-1999 |

| 2 | Lisebelisoa tsa gear le shaft | / | Amohela alloy e phahameng ea matla, carburizing le quenching, ho sila |

| 3 | Ho nepahala ha gear le ho thatafala | / | 6grade, HRC 54-62 |

| 4 | Ho tiisa oli | Ho tiisa hohle ho amohela lihlahisoa tse ntle | |

| 5 | Screw Safeguard | / | Alamo ea ho falla ha screw ka ho iketsa |

| 6 | Brand | DUOLING (JIANGYIN) | |

| 7 | thepa ea thepa | NSK | |

| 8 | thepa e jereng MOSEBETSI | 20CrMnTi Nitriding leino le thata | |

| Sesebelisoa sa ho fepa ka dosing | |||

| 1 | Molaoli oa lebelo la ho fepa | / | Phetoho ea maqhubu a ABB |

| 2 | E ka lokisoa ka thoko kapa ea amahanngoa le tokiso le extrusion. | ||

| 3 | Ho fepa koloi 1.5kwMaterial tšepe e sa hloekang | ||

| Sistimi ea enjene le motlakase | |||

| 1 | Matla a Motlakase | KW | 75(AC motor) |

| 2 | Mokhoa oa ho lokisa lebelo | / | Phetoho ea maqhubu a feto-fetohang |

| 3 | Bokhoni ba Tlhahiso | Kg/h | 400 |

| 4 | Molaoli oa Mocheso | / | RKC, Japane |

| 5 | Hangata inverter | / | ABB |

| 6 | Khokahano ea AC | / | Siemens |

| 7 | Palo ea li-volts | / | Ho latela tlhoko |

| 8 | Mofuta oa likoloi | Siemens | |

| 9 | Bophahamo ba axis ea extruder | mm | 1000 |

| 10 | |||

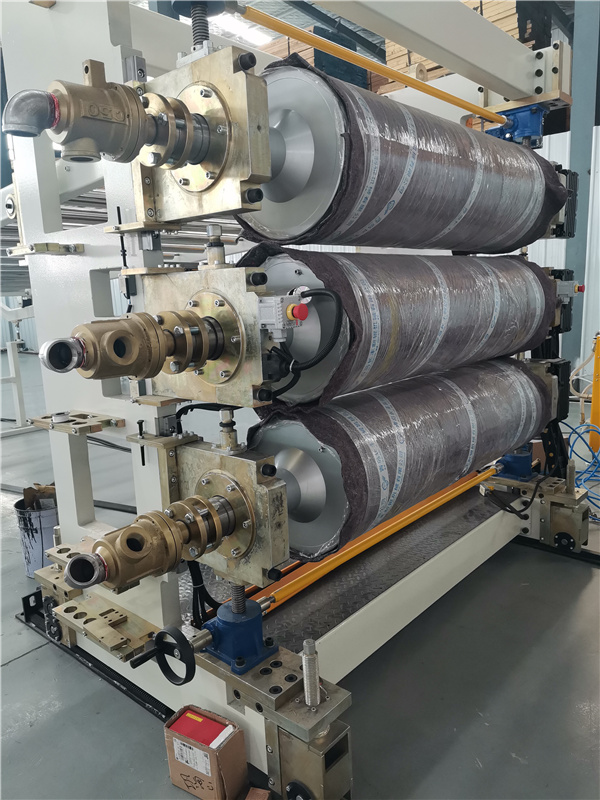

3. Die head and calibrating Molds (ho kenyeletsoa mocheso oa hlobo)

| Ntho | Tlhaloso | |

| Sesebediswa se laolang se nang le choke plug: Sete e le 1 ya molomo o shweleng.Molomo o ka hodimo o ka fetolwa mme wa fa tlase o ka nkelwa sebaka.Ho na le mochine o nang le lefu le nang le phetoho ea die lifting.Molomo oa hlobo o na le sesebelisoa sa oli se potolohang mocheso, se nang le mochine oa mocheso oa hlobo. Bophara bo sebetsang ba hlooho ea die: 1350mm Mokhoa oa mocha: mocha oa hanger oa liaparo o amoheloa Bophara ba sehlahisoa: 1220mm Botenya ba lihlahisoa tsa foam board: 3-25mm Karolo ea ho futhumatsa: Zone 7 The die e entsoe ka tšepe ea boleng bo holimo ea alloy le li-die steel forgings, 'me bokaholimo ba semathi se ka hare ke chrome e pentiloeng le ho belisoa. Sebopeho sa hlobo: sebopeho sa hlobo se monya thekenoloji e tsoang linaheng tse ling, 'me bokahare ba sekoti sa hlobo bo pentiloe ka chromium e thata' me e bentšitsoe seiponeng se khanyang. Tokiso ea botenya: liboutu tse fetolehang li behiloe molomong oa lefu, o ka fetoloang ha o hlahisa lipoleiti tse nang le botenya bo fapaneng. Foromo ea ho futhumatsa: tšepe e se nang tšepe e futhumatsang motlakase e sebelisoa bakeng sa ho futhumatsa, e nang le ts'ebetso e ts'oanang le botsitso bo botle. Mold trolley, mofuta oa bracket, e nang le lebili le tsamaeang. Boitsebiso: lisekoere tube tšepe poleiti tjheseletsa matlafatsoa sebopeho Mokhoa oa ho lokisa: ho lokisa sekoti Phetoho bophahamo: 100mm | ||

Mochini oa boto ea foam oa PVC Likarolo tse ling: Lenane la lisebelisoa:

| NO | Lebitso la likarolo tse ling | Bongata |

| 1 | Lahlela heater ea aluminium bakeng sa sebaka se le seng | 1 likhomphutha |

| 2 | Sefene se phodileng sa moya bakeng sa moqomo | 1 likhomphutha |

| 3 | Spanner bakeng sa hlobo | 1 likhomphutha |

| 4 | likhokahanyo | 2 likhomphutha |

| 5 | Thermocouples | 5 likhomphutha |

| 6 | lithupa tsa ho futhumatsa bakeng sa li-abrasives | 5 likhomphutha |

| 7 | koporo feeler gauge | 1pcs |

| 8 | ho lokisa liboutu | 5 likhomphutha |

| 9 | Ho fepa nakong ea selemo bakeng sa mochini oa ho fepa | 2 likhomphutha |

| 10 | Pepe ea mochini oa ho fepa | 2 likhomphutha |

| 11 | lihokelo tsa lipeipi tsa moea | 5 likhomphutha |